GALVANIZED IRON DUCT

G.I. Rectangular Ducts are fabricated in our factory according

to the requirements of customers. Ducts are fabricated using

high grade G.I. steel coils and processing of operations is

on ultra modern automatic duct making machines operated

by experienced and skilled staff. Each duct piece passes

through strict Quality Control checks and ensures adhere

to specifications and standards, whether it is a normal G.I.

duct or a Fire Rated one. The complete range of ducting

offered by NAFFCO Flow Control is competitively priced

and is insured for full protection against air leakages, fire &

smoke and sound.

ALUMINIUM DUCT

NAFFCO is experienced in fabricating

aluminium ducts which is, as mentioned in ASTM B209,

BS EN485, BS EN515, BS EN573 subject to the uncovered

surroundings.

Aluminium ducts are manufactured from AA1100 sheets

of aluminium/sheets with Tailored ‘S’ & Drive ‘C’ cleats of

equal grade or crosswise joints of FL flange type.

Plain type (Reflector quality) is also generally utilised as

air ducts in places like clean rooms for sensitive industrial

application, swimming pool, etc. Stucco engraved form is

relatively dent & scratch resistant which is mostly used as

cladding on exposed G.I. ducts.

STAINLESS STEEL DUCT

NAFFCO ’s Stainless Steel (SS) ducts are

manufactured from SS coils of 316 / 304 grades with

transverse & fully welded longitudinal joints.

We employ special skilled workforce to manufacture SS

ducts and fittings. Stainless steel Ducts are fabricated as

per the standards of NFPA, BS and ASHRE.

Stainless Steel ducts are widely utilised in open

surroundings to observe zones and in the zones where

Cleanliness is the main concern and in extremely abrasive

environments. Stainless Steel ducts are stronger, stiffer

and finest quality in comparison with G.I. ducts. SS

duct has the characteristics of corrosion resistant & fire

resistance.

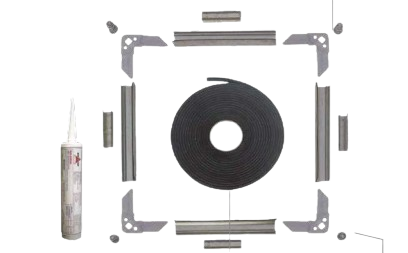

DUCT JOINING

SLIP-ON FLANGES:

Roll-formed G.I. Section with embedded

sealant. Available in different cross-sections to provide a

range of rigidity and strength characteristics.

GASKET:

Self-adhesive, micro-cellular, crosslinked, Polyethylene foam type. (Alternatives:

PVC or Neoprene)

CORNERS:

To be inserted into the hollow we of

the slip-on flange. 4 corner pcs. are required for

each rectangular frame, 8 corner pcs. per joint.

CARRIAGE BOLTS WITH FLANGED NUTS:

Electrogalvanized, square-necked carriage bolts, with

flanged nuts, Each joint required 4 sets.